A Breakthrough For Electric Autos

Newcastle University is to play a key part in the development of the next generation of electric vehicle batteries in the UK. Lithium is considered a comparatively uncommon element (actually a uncommon earth metal) according to the Handbook of Lithium and All-natural Calcium with restricted globe supplies , (discounting the seemingly inexhaustible amount of 230 billion tonnes found in sea water ). The current EV recycling applications will be expanded further as battery use accelerates.

Newcastle University is to play a key part in the development of the next generation of electric vehicle batteries in the UK. Lithium is considered a comparatively uncommon element (actually a uncommon earth metal) according to the Handbook of Lithium and All-natural Calcium with restricted globe supplies , (discounting the seemingly inexhaustible amount of 230 billion tonnes found in sea water ). The current EV recycling applications will be expanded further as battery use accelerates.

Please download the PDF brochure for complete technical specifications and capabilities or download a case presentation in Projects section of this web page. So, for more than 1 billion road cars, as there are globally, replacing them by electric versions would be a stupendous and slow task. I’m confident that a long time ago somebody felt there wasn’t enough lead on earth to supply car batteries either.

This efficiency has helped to reposition electric vehicles …

A Breakthrough For Electric Autos Read More

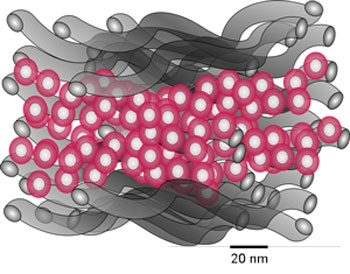

Current advancements working with carbon nanotube electrodes show the capacity for multifunctionality as a lithium-ion storage material and as an electrically conductive support for other high capacity materials like silicon or germanium. It is recognized that the inclusion of carbon as an additive in the creation of electrodes, or as a coating of the electrodes enhances the electronic conductivity and capacity efficiency of Li-ion and other battery systems. Paper Battery Company’s technology is based on never-noticed-before combinations of supercapacitor power and energy densities, combined with ultrathin footprints and placement options. The next step in the method is to cycle the battery while in TEM so that the reside deterioration can be observed.

Current advancements working with carbon nanotube electrodes show the capacity for multifunctionality as a lithium-ion storage material and as an electrically conductive support for other high capacity materials like silicon or germanium. It is recognized that the inclusion of carbon as an additive in the creation of electrodes, or as a coating of the electrodes enhances the electronic conductivity and capacity efficiency of Li-ion and other battery systems. Paper Battery Company’s technology is based on never-noticed-before combinations of supercapacitor power and energy densities, combined with ultrathin footprints and placement options. The next step in the method is to cycle the battery while in TEM so that the reside deterioration can be observed.