Exploring the Advantages of Deep Cycle Batteries for RVs and Boats: Powering Your Adventures with Efficiency and Reliability

Deep cycle batteries play a crucial role in powering RVs and boats, providing the energy needed for a variety of onboard systems and appliances. Unlike regular automotive batteries, deep cycle batteries are designed to provide a steady and reliable power supply over an extended period. In this article, we explore the advantages of deep cycle batteries for RVs and boats, showcasing why they are the ideal choice for those seeking efficiency and reliability during their adventurous journeys.

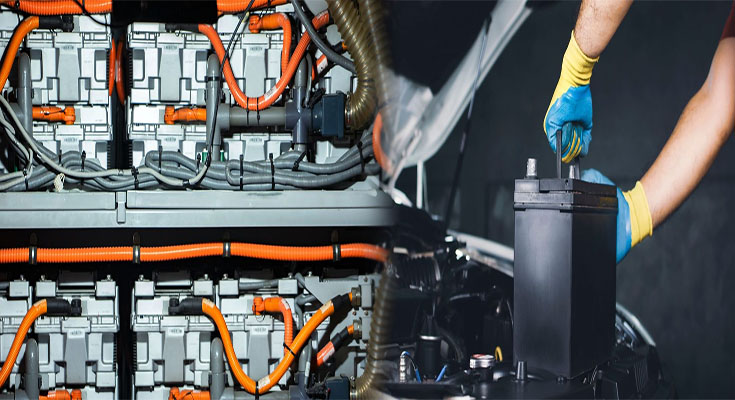

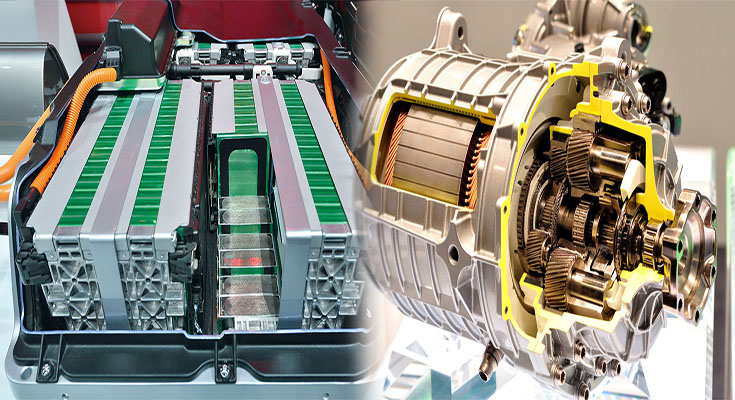

The Powerhouse: Understanding Deep Cycle Batteries

Deep cycle batteries differ from car batteries in that they are designed to deliver a consistent level of power over a longer duration. They are specifically designed to handle deep discharges and subsequent recharging cycles, making them ideal for applications that require reliable and sustainable power supply, such as RVs and boats.

Advantages of Deep Cycle Batteries

1. Deep Discharge Capability

One of the key advantages of …

Exploring the Advantages of Deep Cycle Batteries for RVs and Boats: Powering Your Adventures with Efficiency and Reliability Read More